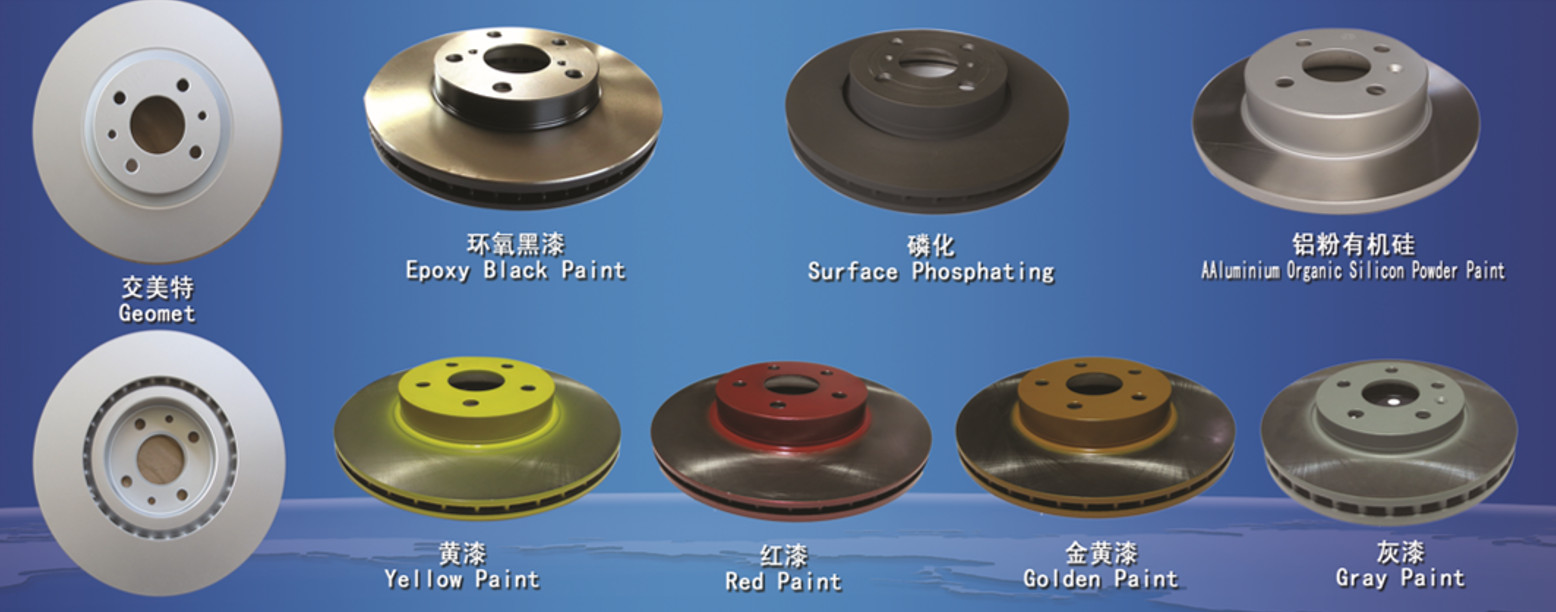

Personlized Products Painted Brake Rotors - Painted & Drilled & Slotted Brake disc – SANTA Detail:

Painted brake disc, drilled and slotted

As brake rotors are made of iron, they naturally rust and when exposed to minerals such as salt, the rusting (oxidization) tends to speed up. This leaves you with a very ugly looking rotor.

Naturally, companies started looking at ways to mitigate rusting of the rotors. One way was to get brake disc pained to prevent rust.

Also for higher performance, please will like the drilled and slotted style rotors.

Why do drilled or slotted discs improve braking

The presence of holes or slots on a brake disc is a guarantee of better grip and certainly a more responsive and effective braking system. This effect is due to the surface of the holes or slots which ensure, especially in the initial braking phases, better performance thanks to a higher friction coefficient than that of standard discs.

Another important advantage to using drilled and slotted discs is the constant renewal of the pad friction material. The holes also interrupt the sheet of water that can deposit on the braking surface in the rain. For this reason, even in the case of wet roads, the system responds efficiently from the very first braking operation. In the same way, the slots, which face outward, ensure more effective dispersion of any water that may be on the disc surface: the result is more uniform behavior in any weather conditions.

When they reach high temperatures, these gases created by the combustion of the resins that make up the friction material, can cause the phenomenon of fading, which reduces the friction coefficient between disc and pad, with a consequent loss of braking efficiency. The presence of holes or slots on the braking surface allows for rapid expulsion of these gases, quickly restoring optimum braking conditions.

| Product Name | Painted brake disc, drilled and slotted |

| Other names | Painted brake rotor, rotor brake, drilled and slotted |

| Shipping Port | Qingdao |

| Packing Way | Neutral Packing: plastic bag and carton box, then pallet |

| Material | HT250 equivalent to SAE3000 |

| Delivery time | 60days for 1 to 5 containers |

| Weight | Original OEM weight |

| Warrant | 1 year |

| Certification | Ts16949&Emark R90 |

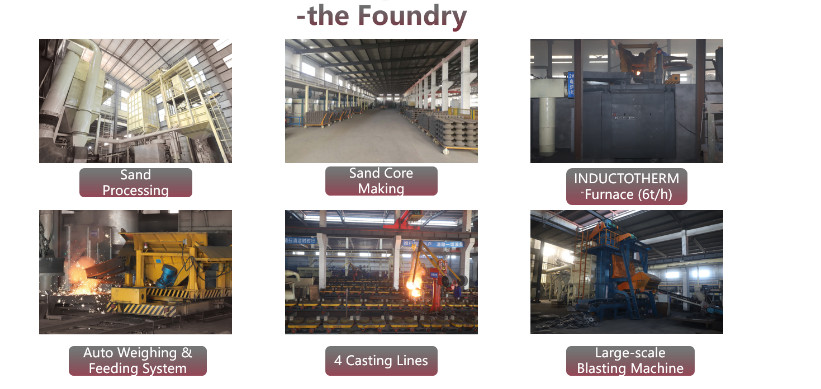

Production process:

Santa brake has 2 foundries with 5 horizontal casting lines, 2 machine workshop with more than 25 machining lines

Quality control

Each piece will be inspected before leaving the factory

Packing: All kinds of packing are available.

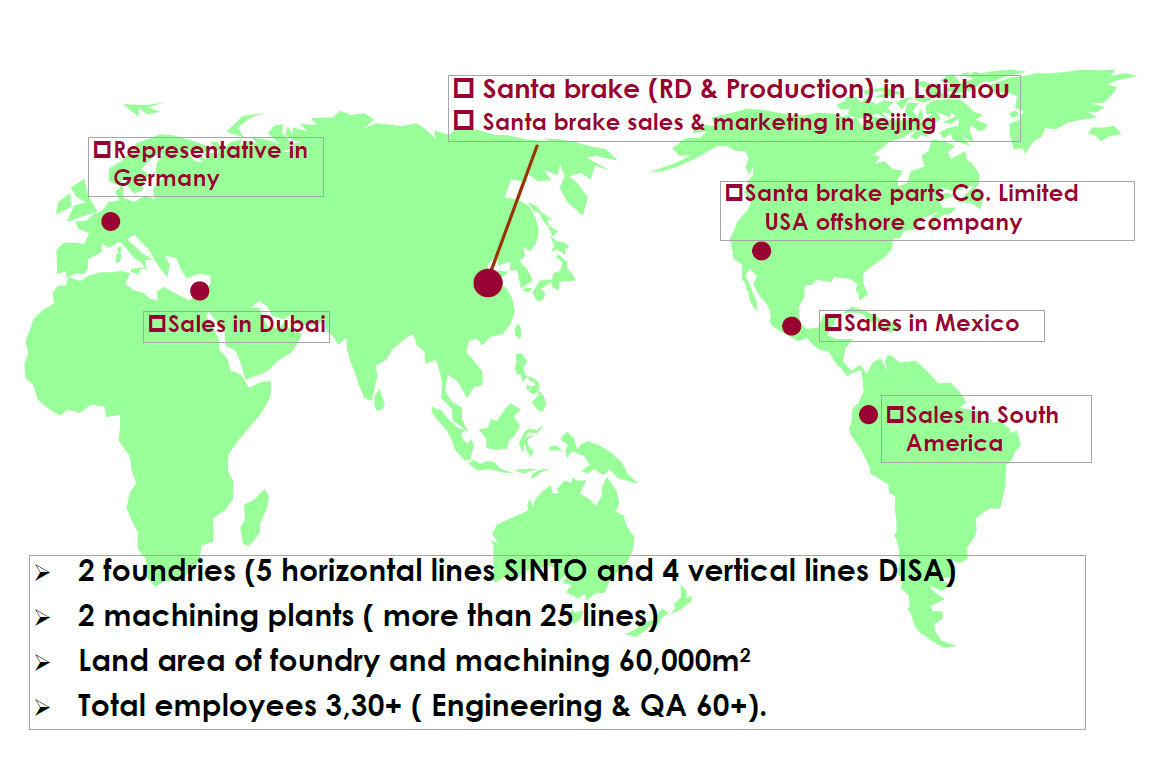

After years of development, Santa brake has customers all around the world. To meet customer’s demand, we set up sales representative in Germany, Dubai, Mexico, and South America. In order to have flexible tax arrangement, Santa bake also have offshore company in USA and Hongkong.

Relying on Chinese production base and RD centers, Santa brake is offering our customers good quality products and trustworthy services.

Our Advantage:

15 years brake discs production experience

Customers worldwide, full range. Comprehensive category of over 2500 references

Focusing on brake discs,quality oriented

Knowing about the brake systems, brake discs development advantage, quick development on new references.

Excellent cost control ability, relying on our expertise and reputation

Product detail pictures:

Related Product Guide:

We normally follow the basic principle "Quality Initial, Prestige Supreme". We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for Personlized Products Painted Brake Rotors - Painted & Drilled & Slotted Brake disc – SANTA, The product will supply to all over the world, such as: Lyon, Ireland, Malaysia, The company has numbers of foreign trade platforms, which are Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" HID brand products sell very well in Europe, America, Middle East and other regions more than 30 countries.

We have been looking for a professional and responsible supplier, and now we find it.

-

OEM China Drilled Brake Rotors - Geomet Coatin...

-

OEM China Brake Drum For Truck - Brake drum wi...

-

One of Hottest for Brake Pad Shims - Semi-meta...

-

Massive Selection for Pad Brake - Semi-metalli...

-

Factory selling Car Brake Pads And Rotors - Se...

-

Rapid Delivery for Other Auto Brake Parts - Tr...