Low-metallic brake pads

Low Metallic (Low-Met) brake pads are suited to performance and high-speed driving styles, and contain high levels of mineral abrasives to provide better stopping power.

Santa brake formula contains these ingredients to provide exceptional stopping power and shorter stopping distances. It is also more resistant to brake fade at high temperatures, delivering consistent brake pedal feel lap after hot lap. Our low metallic brake pads is recommended for high performance vehicles that do spirited driving or track racing, where braking performance is paramount.

| Product Name | Low-metallic brake pads for all kinds of vehicles |

| Other names | Metallic brake pads |

| Shipping Port | Qingdao |

| Packing Way | Color box packing with customers brand |

| Material | Low-metallic formula |

| Delivery time | 60days for 1 to 2 containers |

| Weight | 20tons for each 20 feet container |

| Warrant | 1 year |

| Certification | Ts16949&Emark R90 |

Production process:

Quality control

Each piece will be inspected before leaving the factory

Packing: All kinds of packing are available.

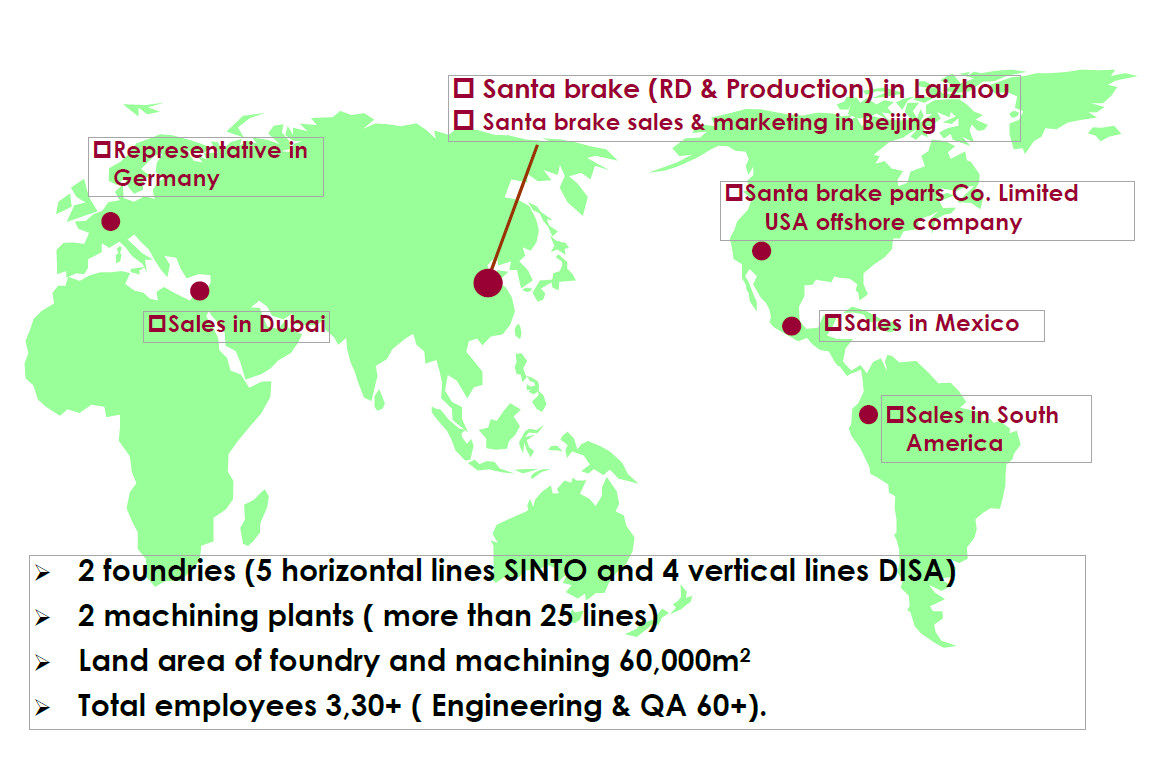

After years of development, Santa brake has customers all around the world. To meet customer’s demand, we set up sales representative in Germany, Dubai, Mexico, and South America. In order to have flexible tax arrangement, Santa bake also have offshore company in USA and Hongkong.

Relying on Chinese production base and RD centers, Santa brake is offering our customers good quality products and trustworthy services.

Our Advantage:

15 years brake parts production experience

Customers worldwide, full range. Comprehensive category of over 2500 references

Focusing on brake pads, quality oriented

Knowing about the brake systems, brake pads development advantage, quick development on new references.

Excellent cost control ability, relying on our expertise and reputation

Steady and short lead time plus perfect after sales service

Strong catalogue support

Professional and dedicated sales team for efficient communication

Willing to accommodate customers’ special requirements

Keeping improving and standardizing our process

Which Brake Pads

When it comes to fitting brake pads there is no substitute for research. Ask your local garage, canvass opinion on forums and read up on the pros and cons of each type before making a decision.

That said there is a general acceptance that lighter, compact vehicles are best suited to organic brake pads. They will afford the stopping power required, whilst producing minimal sound. They are also relatively cheap to purchase.

Medium sized cars meanwhile need that little bit extra in the way of stopping power. A low metallic is therefore most appropriate, just be prepared for increased volume.

If you’re lucky enough to own a sports car and crave more in the way of acceleration, plump for semi-metallic or high-performance ceramic brake pads. Both will ensure you come to a halt before taking off.

Finally, lorry drivers and those lugging significant loads need more in the way of metal content. Severe duty pads may even be necessary to provide that additional protection.

The average lifespan of a set of brake pads is around the 50,000 mile mark. Newer models come with a warning light that indicates when a change is necessary but loud screeching, bad vibration, obvious wear and tear and a car’s tendency to pull to one side provide further clues.

So keep an eye on your brake pads, they matter more than you might think.