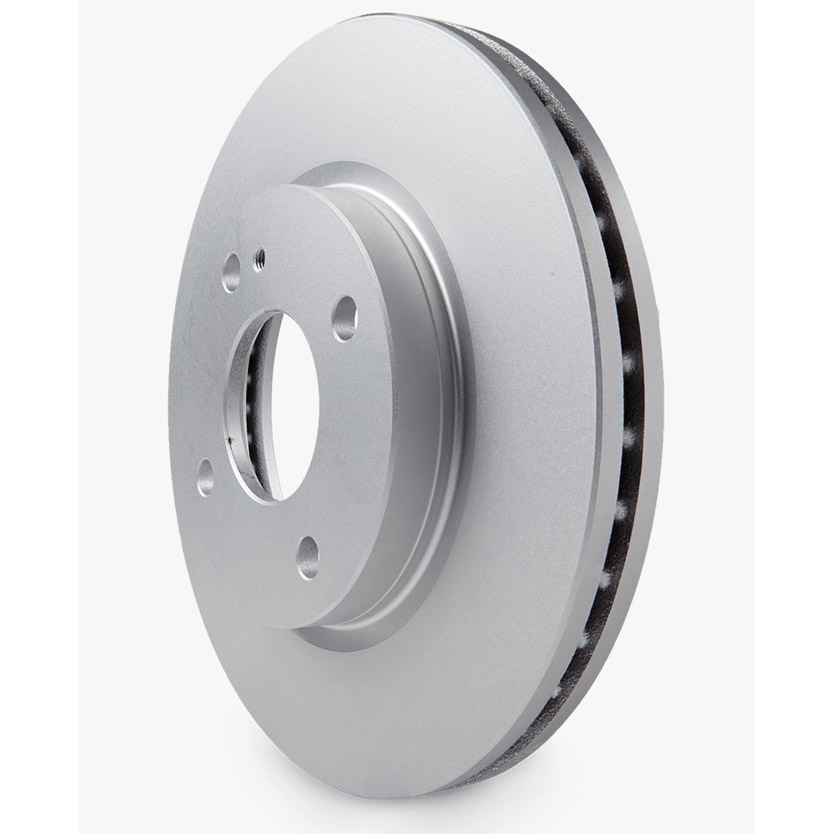

Geomet brake disc

As brake rotors are made of iron, they naturally rust and when exposed to minerals such as salt, the rusting (oxidization) tends to speed up. This leaves you with a very ugly looking rotor.

Naturally, companies started looking at ways to mitigate rusting of the rotors. One way was to apply a Geomet coating to prevent rust.

What is Geomet coating?

GEOMET coating is a water based chemical coating that is applied to brake rotors to help prevent corrosion.

The coating was developed by NOF Metal Coatings Group in response to stricter environmental regulations and concerns. The resulting product is one that is used worldwide on more than 40 million brake discs per year.

It complies with REACH and The End of Life Vehicles Directive of the European Union. REACH is a regulation “adopted to improve the protection of human health and the environment from the risks that can be posed by chemicals”. The End of Life Vehicles Directive (2000/53/EC) is a Directive addressing the end of life for automotive products.

What are the benefits?

● It looks better: Most cars these days ride on alloy wheels with lots of space to see through to the brakes. The last thing you’d like to see under those wheels are rusted rotors. GEOMET minimizes rusting and keeps your rotors looking good.

● Good initial braking performance: GEOMET is not greasy and it forms a pretty thin film of coating once dried. This means that the coating is thin enough that it doesn’t damage the quality of braking during the brake’s first use.

● High temperature resistance: The coating can withstand up to 400°C (750°F) and still provide excellent corrosion resistance without crystallization during heat cycles or formation of organic resins. This means that the coating won’t chip and will wear evenly.

● Environmentally conscious coating: There is no chromium in the solution and since it is applied in a closed system, the leftover liquid is recycled. During curing, the only thing that evaporates is water, not chemicals.

● Thin and non-greasy: Once cured, GEOMET is thin and non-greasy which makes it a great option for aftermarket products where the rotors are handled, shipped, and stored before being delivered to the customer. The coating keeps things clean and relatively light and will make sure you get your brakes in great shape.

| Product Name | Geomet brake disc for all kinds of vehicles |

| Other names | Geomet Brake rotor, disc bake, rotor brake |

| Shipping Port | Qingdao |

| Packing Way | Neutral Packing: plastic bag and carton box, then pallet |

| Material | HT250 equivalent to SAE3000 |

| Delivery time | 60days for 1 to 5 containers |

| Weight | Original OEM weight |

| Warrant | 1 year |

| Certification | Ts16949&Emark R90 |

Production process:

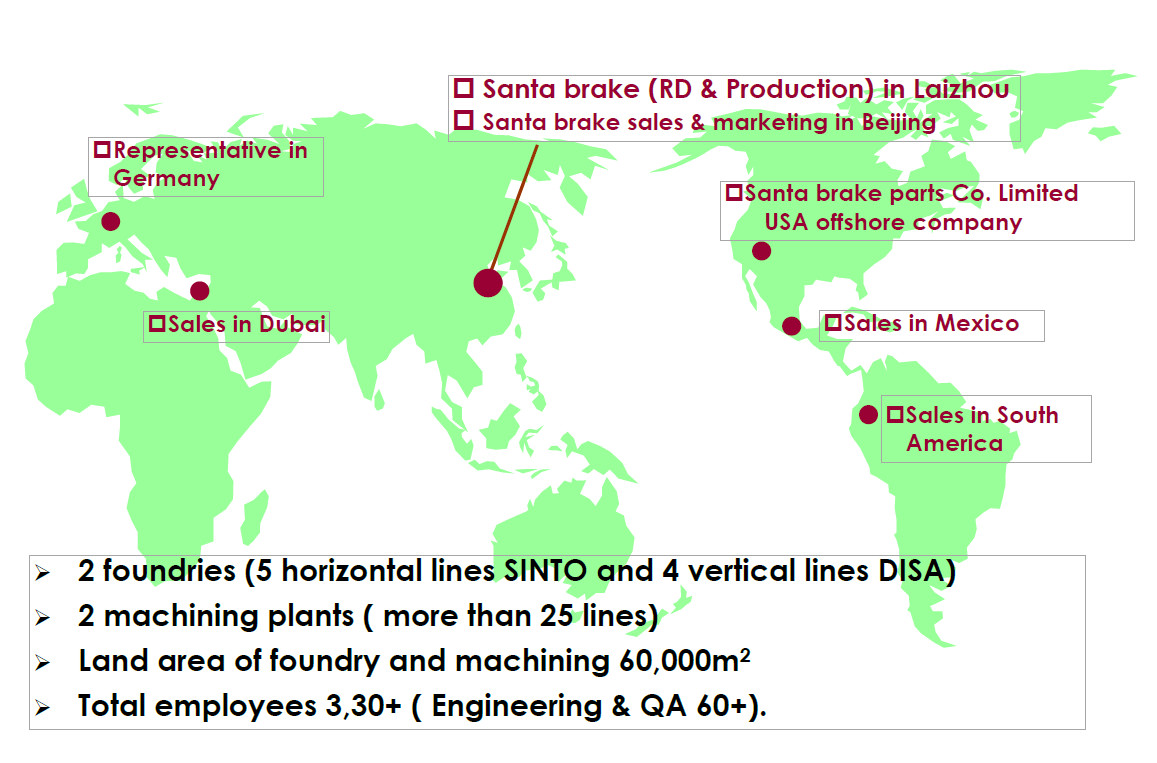

Santa brake has 2 foundries with 5 horizontal casting lines, 2 machine workshop with more than 25 machining lines

Quality control

Each piece will be inspected before leaving the factory

Packing: All kinds of packing are available.

After years of development, Santa brake has customers all around the world. To meet customer’s demand, we set up sales representative in Germany, Dubai, Mexico, and South America. In order to have flexible tax arrangement, Santa bake also have offshore company in USA and Hongkong.

Relying on Chinese production base and RD centers, Santa brake is offering our customers good quality products and trustworthy services.

Our Advantage:

15 years brake discs production experience

Customers worldwide, full range. Comprehensive category of over 2500 references

Focusing on brake discs,quality oriented

Knowing about the brake systems, brake discs development advantage, quick development on new references.

Excellent cost control ability, relying on our expertise and reputation