Our growth depends within the innovative equipment, fantastic talents and repeatedly strengthened technology forces for Chinese Professional China Brake Pads Factory manufacturer, Welcome all nice buyers communicate specifics of products and ideas with us!!

Our growth depends within the innovative equipment, fantastic talents and repeatedly strengthened technology forces for China D1473, D946, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality solutions. Our business aims to “honest and trustworthy, favorable price, customer first”, so we won the trust of the majority of customers! If you are interested in our solutions and services, please do not hesitate to contact us!

Ceramic brake pads

Ceramic brake pads are made from ceramic very similar to the type of ceramic used to make pottery and plates, but are denser and a lot more durable. Ceramic brake pads also have fine copper fibers embedded within them, to help increase their friction and heat conductivity.

Since they were developed in the mid-1980s, ceramic brake pads have been consistently increasing in popularity for a number of reasons:

● Noise-Level: Ceramic brake pads are very quiet, creating little-to-no extra sound when the brakes are applied.

● Wear & Tear Residue: Compared to organic brake pads, ceramic brake pads tend to produce less dust and other particles over time as they wear down.

● Temperature & Driving Conditions: Compared to organic brake pads, ceramic brake pads can b

| Product: | Ceramic brake pads for all kinds of vehicles |

| Other names | Ceramic brake pads |

| Shipping Port | Qingdao |

| Packing Way | Color box packing with customers brand |

| Material | Semi-metallic |

| Delivery time | 60days for 1 to 2 containers |

| Weight | 20tons for each 20 feet container |

| Warrant | 1 year |

| Certification | Ts16949&Emark R90 |

Production process

Quality control

Each piece will be inspected before leaving the factory

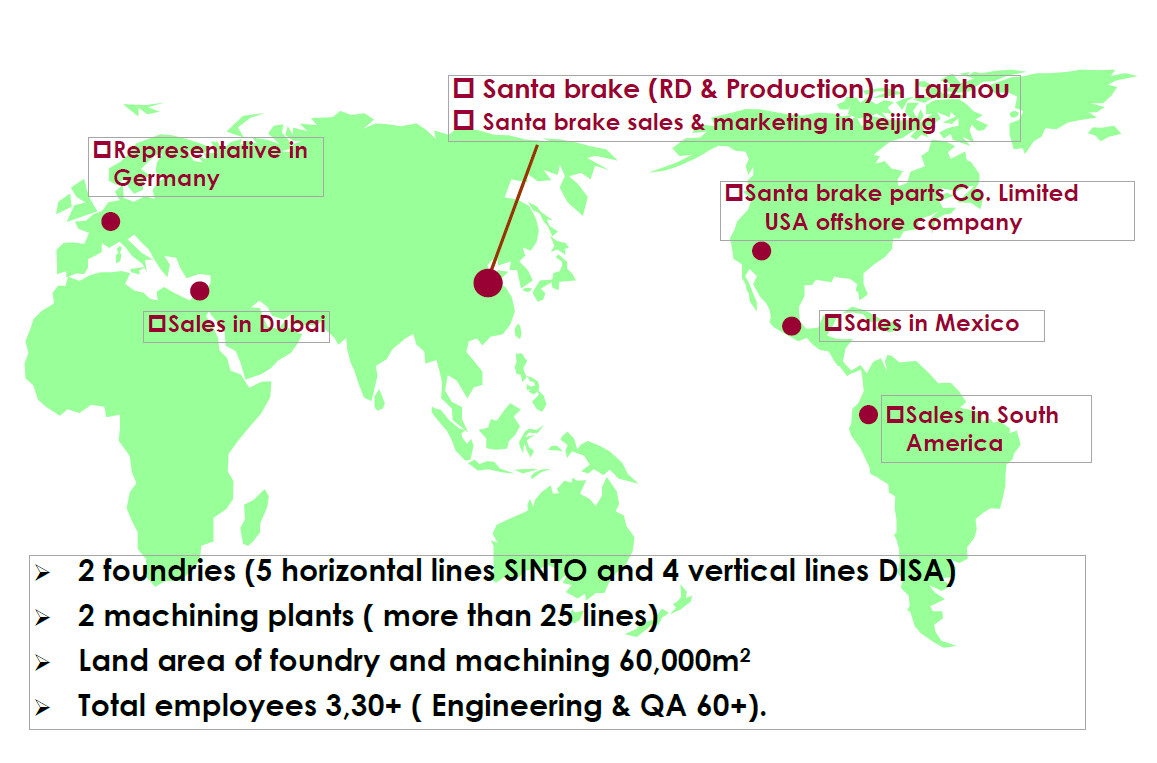

Santa Brake Overview

After years of development, Santa brake has customers all around the world. To meet customer’s demand, we set up sales representative in Germany, Dubai, Mexico, and South America. In order to have flexible tax arrangement, Santa bake also have offshore company in USA and Hongkong.

Relying on Chinese production base and RD centers, Santa brake is offering our customers good quality products and trustworthy services.

Our Advantage:

15 years brake parts production experience

Customers worldwide, full range. Comprehensive category of over 2500 references

Focusing on brake pads,quality oriented

Knowing about the brake systems, brake pads development advantage, quick development on new references.

Excellent cost control ability, relying on our expertise and reputation

Steady and short lead time plus perfect after sales service

Strong catalogue support

Professional and dedicated sales team for efficient communication

Willing to accommodate customers’ special requirements

Keeping improving and standardizing our process

What are the differences between semi-metallic and ceramic brake pads?

The difference between ceramic and semi-metallic brake pads is simple – it all comes down to the materials that are used to produce each brake pad.

When choosing a ceramic or semi-metallic brake pad for a vehicle, there are certain applications in which ceramic and semi-metallic pads both offer different advantages.

For performance vehicles, track driving or when towing, most drivers prefer semi-metallic brakes, as they provide better braking over a wider range of temperatures and conditions. They are made of material that conducts heat well, thus making them more able to withstand higher temperatures upon braking, while helping the system cool simultaneously. Semi-metallic brake pads can be noisier than ceramic brake pads and their price point normally falls between that of organic and ceramic brake pads.

Ceramic brake pads, while quieter, are also able to handle extremely high temperatures with quick recovery, causing less damage to the rotors. As they wear, ceramic brake pads create a finer dust than semi-metallic brake pads, leaving less debris on the vehicle’s wheels. Ceramic brake pads typically last longer than semi-metallic brake pads, and through their lifespan, provide better noise control and less wear-and-tear to rotors, without sacrificing braking performance. When deciding ceramic versus semi-metallic brake pads, bear in mind that not all vehicle makes and models are compatible with ceramic brake pads, so research is advised.

Understanding how brake pads function and how different brake pad materials are suited for different applications will help you make the right brake pad selection to fit your customer’s unique vehicle and driving needs.

Our growth depends within the innovative equipment, fantastic talents and repeatedly strengthened technology forces for Chinese Professional China Brake Pads Factory manufacturer, Welcome all nice buyers communicate specifics of products and ideas with us!!

Chinese Professional China D1473, D946, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality solutions. Our business aims to “honest and trustworthy, favorable price, customer first”, so we won the trust of the majority of customers! If you are interested in our solutions and services, please do not hesitate to contact us!

-

Factory wholesale China Truck and Trailer TUV A...

-

Professional China China Brake Systems Manufact...

-

2019 China New Design Auto High Quality Disc Pa...

-

Top Suppliers China Carbon Ceramic Brake Rotor ...

-

Factory making China Brake Disc Supplier for Hi...

-

Best quality China Brake Drum 81501100144 for T...